CO2 rock breaking system is a new technology which can replace soundless cracking agency and explosive.

Dingli CO2 rock breaking system is a new rock breaking technology that can replace explosive blasting. Our company started research and development in coal mines in 1996. This technology is mainly developed to avoid explosion accidents caused by flames generated by explosive blasting in high gas mines. After three years of numerous failures and thousands of experiments, the 51# rock-breaking steel pipe was finally successfully developed. In 2014, the carbon dioxide rock breaking system was further improved and upgraded, the 108# rock breaking steel pipe was developed for open-pit rock breaking. There is no vibration, shock wave, open flame or harmful gas when the carbon dioxide rock breaking system works, which is safe and environmental. The steel pipes are reusable, which helps to reduce the cost. The advent of the 108# CO2 rock breaking system perfectly solves the problem of prohibition of blasting in quarries and mines and the low efficiency of excavator hydraulic breaker. Now the carbon dioxide rock breaking system has been widely used in quarries, mines, highway construction, building foundation, tunnel excavation and other fields.

WORKING PRINCIPLE

Liquid carbon dioxide is a liquid formed from highly compressed and cooled gaseous carbon dioxide. It does not form under atmospheric conditions. It exists only at pressures above 5.1 atm and temperatures below 31.1 °C (critical point temperature) and above -56.6 °C (triple point temperature). CO2 rock breaking technology uses this feature to put the heating pipes into the rock-breaking steel pipes and fill the liquid carbon dioxide into the rock-breaking steel pipes. Insert the steel pipes into the pre-drilled holes on the rocks. When the start button on the initiator is pressed, the temperature of heating pipes will increased rapidly. The liquid carbon dioxide will vaporize and expand rapidly at high temperature. Consequently, the rocks will be broken and splitted.

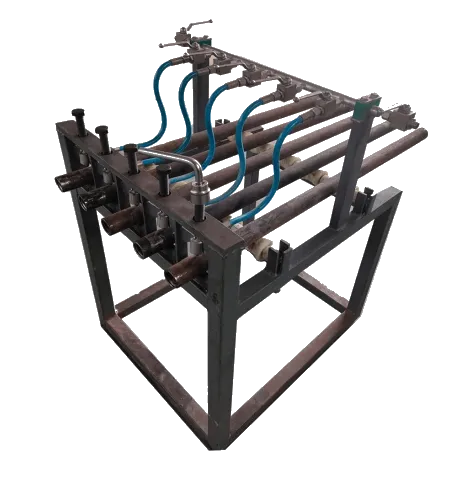

COMPONENTS

Dingli CO2 rock breaking system mainly includes carbon dioxide filling equipment, rock breaking steel pipes and accessories.

ADVANTAGES

No explosive.

No hazardous chemicals.

No vibration.

Easy and quick to operate.

No need bureaucratic procedure or license

No pollution or emission of dust.

Rock-breaking steel pipes are reuseable.

High output compared with conventional machinery.

Dingli CO2 rock breaking system is a new rock breaking technology that can replace explosive blasting. Our company started research and development in coal mines in 1996. This technology is mainly developed to avoid explosion accidents caused by flames generated by explosive blasting in high gas mines. After three years of numerous failures and thousands of experiments, the 51# rock-breaking steel pipe was finally successfully developed. In 2014, the carbon dioxide rock breaking system was further improved and upgraded, the 108# rock breaking steel pipe was developed for open-pit rock breaking. There is no vibration, shock wave, open flame or harmful gas when the carbon dioxide rock breaking system works, which is safe and environmental. The steel pipes are reusable, which helps to reduce the cost. The advent of the 108# CO2 rock breaking system perfectly solves the problem of prohibition of blasting in quarries and mines and the low efficiency of excavator hydraulic breaker. Now the carbon dioxide rock breaking system has been widely used in quarries, mines, highway construction, building foundation, tunnel excavation and other fields.

WORKING PRINCIPLE

Liquid carbon dioxide is a liquid formed from highly compressed and cooled gaseous carbon dioxide. It does not form under atmospheric conditions. It exists only at pressures above 5.1 atm and temperatures below 31.1 °C (critical point temperature) and above -56.6 °C (triple point temperature). CO2 rock breaking technology uses this feature to put the heating pipes into the rock-breaking steel pipes and fill the liquid carbon dioxide into the rock-breaking steel pipes. Insert the steel pipes into the pre-drilled holes on the rocks. When the start button on the initiator is pressed, the temperature of heating pipes will increased rapidly. The liquid carbon dioxide will vaporize and expand rapidly at high temperature. Consequently, the rocks will be broken and splitted.

COMPONENTS

Dingli CO2 rock breaking system mainly includes carbon dioxide filling equipment, rock breaking steel pipes and accessories.

ADVANTAGES

No explosive.

No hazardous chemicals.

No vibration.

Easy and quick to operate.

No need bureaucratic procedure or license

No pollution or emission of dust.

Rock-breaking steel pipes are reuseable.

High output compared with conventional machinery.

Inquiry - CO2 Rock Breaking System